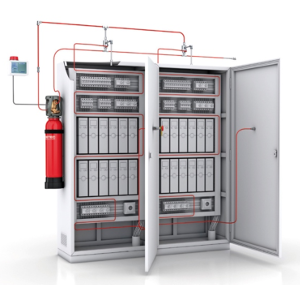

Why the FireDETEC Directional Valve System Attracts so much Interest

But, we realized we could save our customers even more money by developing a directional valve system that protects multiple objects from one cylinder. The cylinder/valve assembly represents a large part of the total system cost – so it represents a major savings when you reduce the number of cylinders required.

In fact, with FireDETEC directional valves, if you have a configuration where 3 electrical cabinets are placed side-by-side, you could save 60% versus buying 3 individual systems.

At recent trade shows, a lot of visitors expressed interest in our directional valve systems. We demonstrated that multiple, separate protection zones can be protected with just a single FireDETEC cylinder/valve assembly with no loss in performance. Each protection zone is equipped with a directional valve that is closed when the system is armed. If a fire starts in one of the zones, the FireDETEC sensor tube bursts and the directional valve opens. This triggers the main cylinder valve to discharge the CO2 fire extinguishing agent. The discharge is routed only through the open directional valve into the zone where there is a fire. The other directional valves remain closed. The fire is quickly suppressed in the zone with the fire, while the other zones remain untouched.

Many visitors were impressed by the simple, yet effective design. It requires no electronics and operates on a simple, cost-effective pneumatic pressure differential technology. FireDETEC with directional valves are dependable because there are simply fewer things that can go wrong. Plus, all systems are manufactured by Rotarex, under strict quality controls using the highest quality materials, and are 100% performance tested.

Our standard FireDETEC fire suppression systems were already very cost-effective for three reasons:

- The concept of local object protection systems focuses the investment only where there is a fire risk – and prevents over-investing in larger systems

- FireDETEC pneumatic differential pressure technology is simpler and less costly than more complicated electronic systems

- Rotarex is the world leader in pressurized gas valve technologies, so we are better able to design and manufacture high-performing valves at the best-cost – without the usual middle-man mark-up. And now, with the option to use our directional valve technology, customers can realize even greater economies.

If you want to know more about FireDETEC fire protection systems with directional valve technology, please contact us.