GAS VALVES AND EQUIPMENT FOR INDUSTRIAL GAS APPLICATIONS

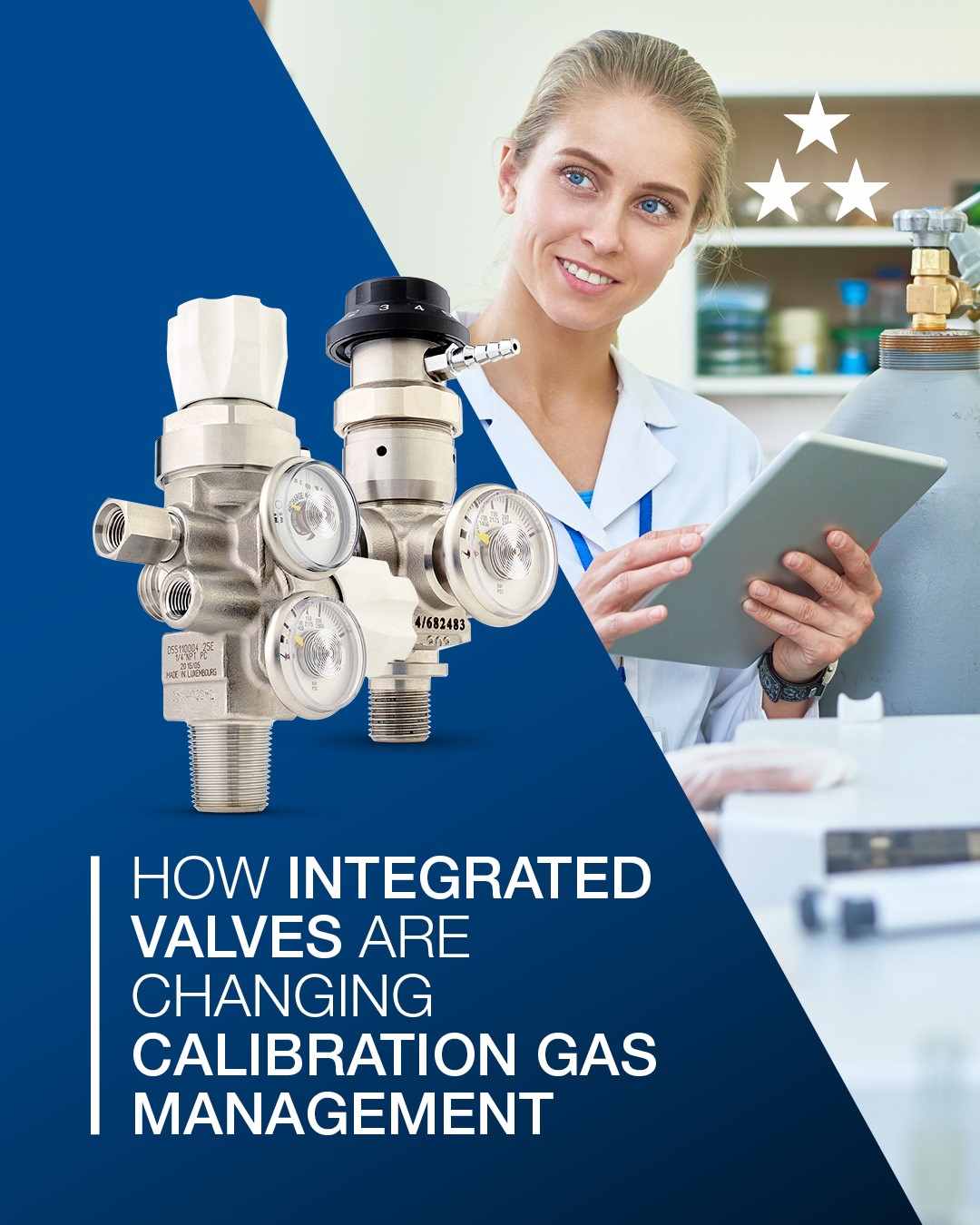

Industrial gases are used in a wide range of industrial applications, from metallurgy and food processing to chemical and pharmaceutical processing. They require precise and reliable gas control, as well as a high level of gas safety, to ensure smooth operations and protect operators.

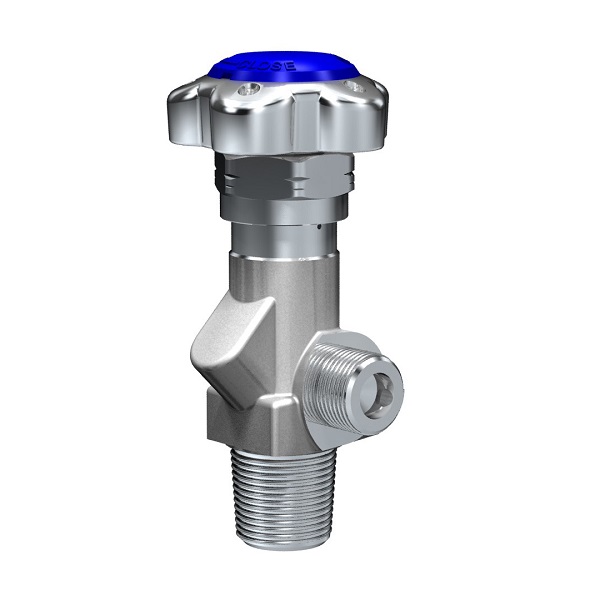

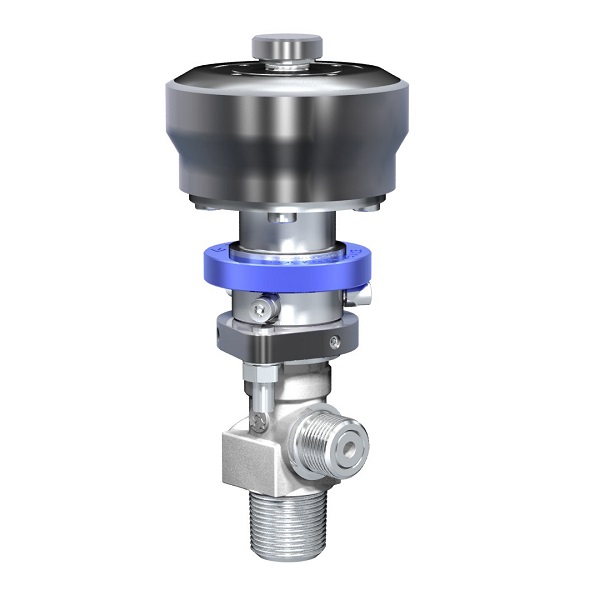

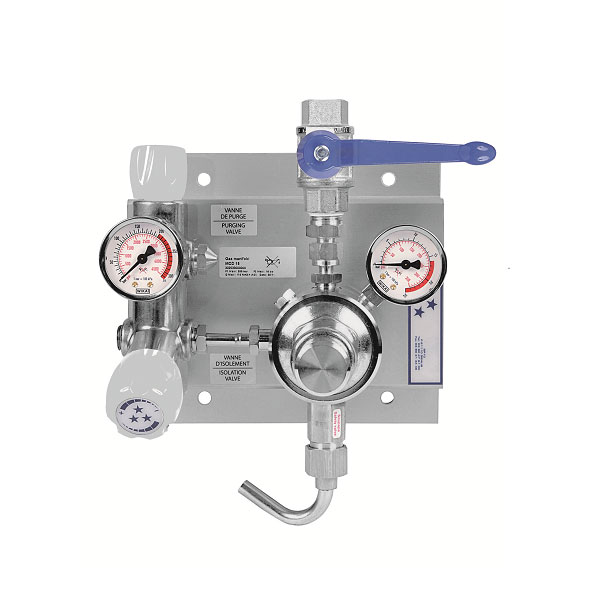

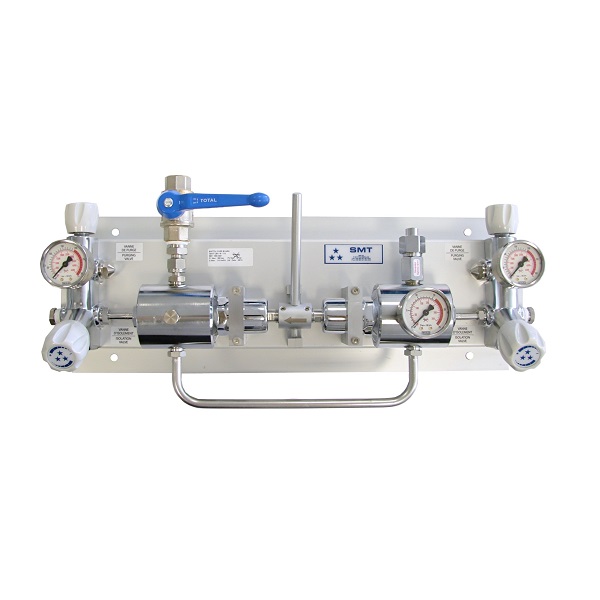

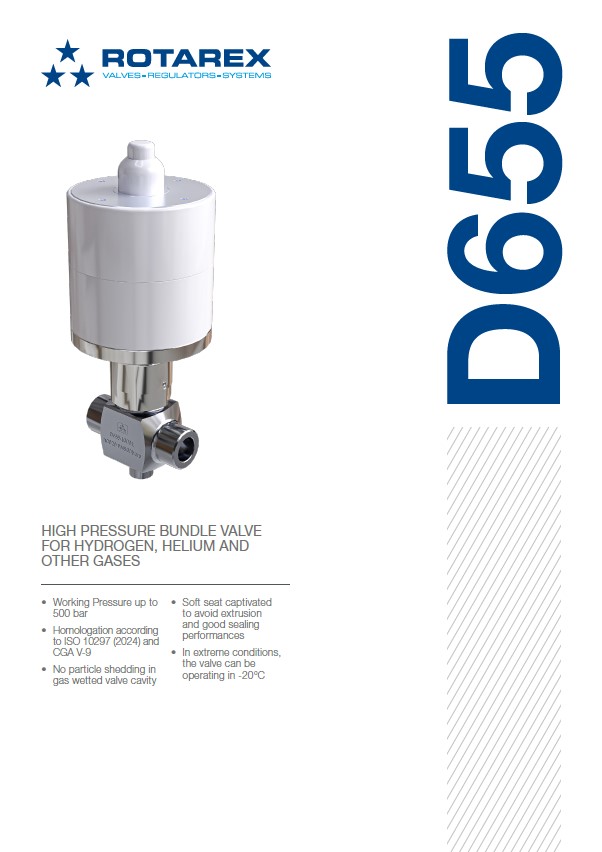

To meet these requirements, industrial gas supply systems rely on high-performance components such as cylinder valves, pressure regulators and switchover boards. Manufactured in robust materials such as stainless steel and available in a wide range of sizes and configurations, these solutions ensure compatibility with different gas cylinders and distribution systems.

Each industrial application has its own requirements in terms of inlet pressure, outlet pressure, flow accuracy and material compatibility depending on the type of gas used. This makes it essential to rely on dedicated gas solutions, engineered with appropriate materials such as stainless steel, to ensure durability and long-term performance.

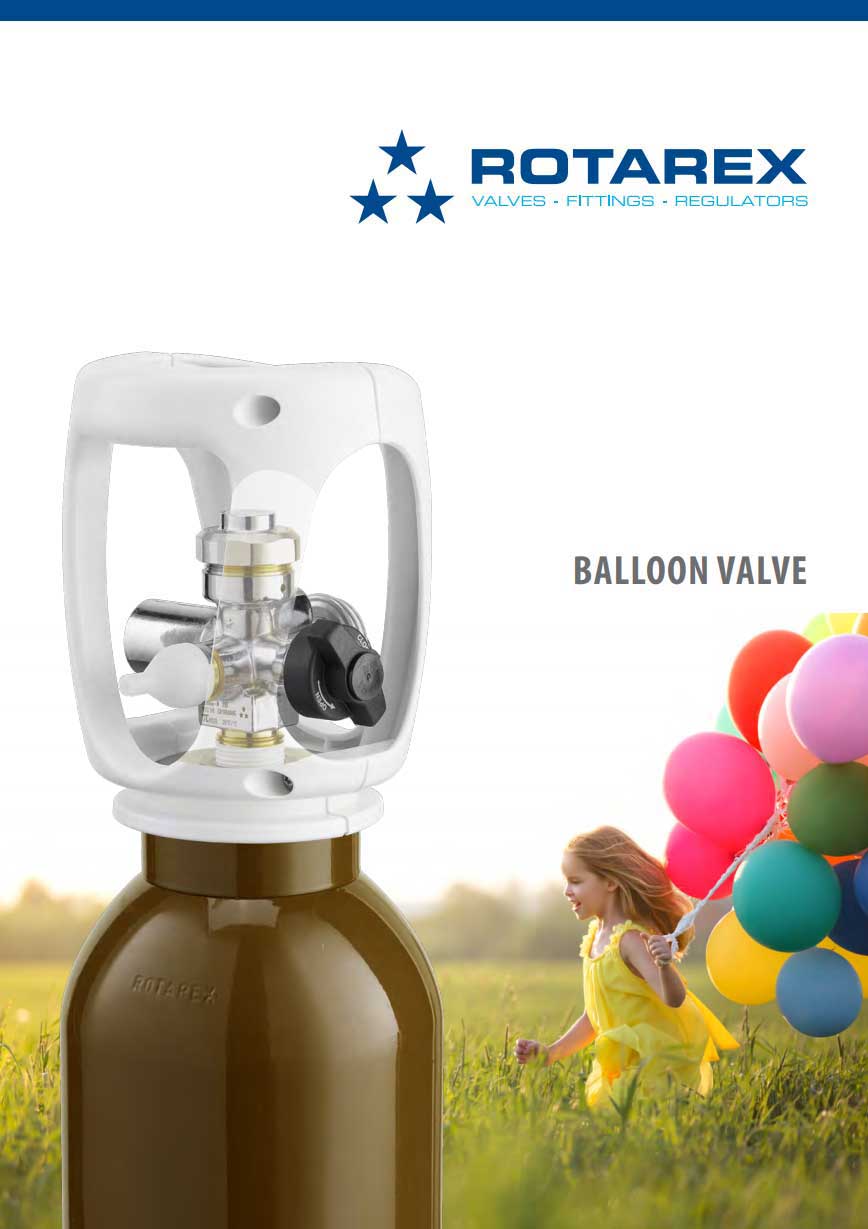

Rotarex designs and manufactures a wide range of innovative gas solutions, including valves, pressure regulators and switchover boards, tailored to the requirements of many industrial sectors. Discover our full range of products below.

250x250_Qpcitu.png)