Cylinder Valves: Discover Our Full Range for All Gas Applications

Gas cylinder valves are essential components for controlling the flow of gas in the gas cylinders. The primary function of a cylinder valve is to open or close to allow the stored gas to escape or to contain it inside. Cylinder valves are essential for maintaining safe operation and ensuring proper gas delivery across various applications such as welding, cutting, manufacturing processes, etc.

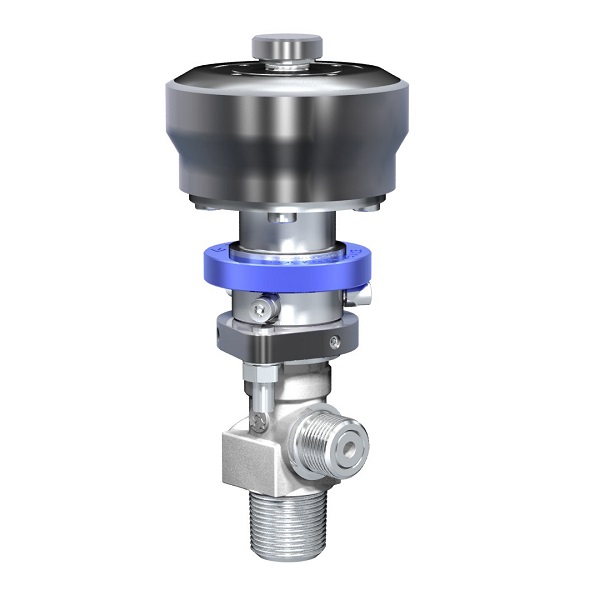

Whether you're looking for standard gas cylinder valves, small cone valves, residual pressure valve, packed seal valves or valve with integrated pressure regulator, or custom solutions, Rotarex wide variety of products offer reliable performance, material compatibility, and full compliance with international safety and quality standards.

Explore our selection below to find the right gas cylinder valve solution for your specific requirements.

.jpg)

.jpg)