A full range of acetylene safety equipment

When using Acetylene, safety is essential. C2H2 is a highly flammable gas and the risk of explosion is high. To keep installations secure, the use of flashback arrestors is mandaroty, preventing any flame from returning to the gas sources.

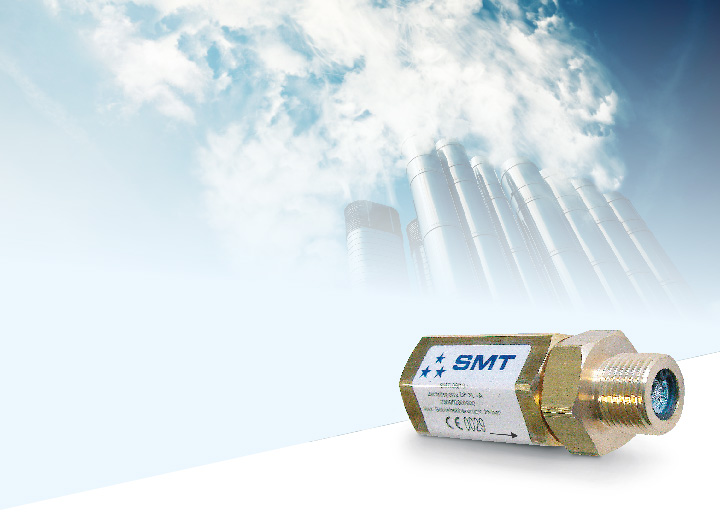

Rotarex has developed a range of safety equipment designed for C2H2 production and filling plants. These include advanced flame arrestors for both high-pressure and low-pressure piping, engineered to stop a flame in either direction while avoiding excessive pressure build-up in the system. Built to the highest international standards, they provide reliable protection for operators, equipment, and infrastructure.

Explore the range today and give your operations the highest level of safety.

.jpg)

.jpg)

.jpg)