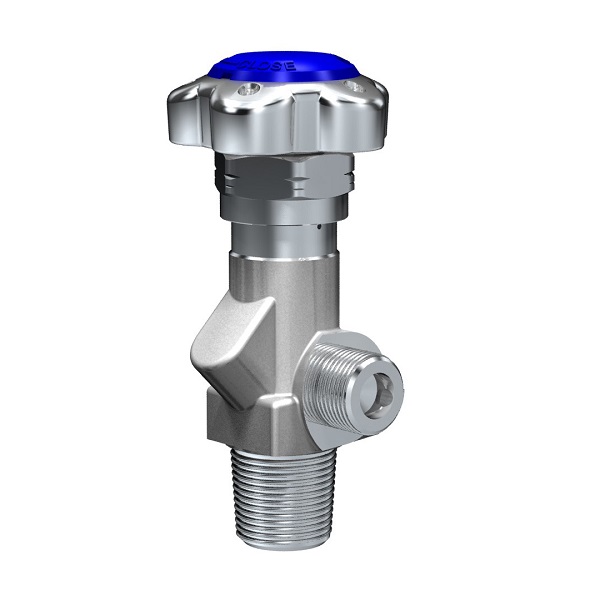

RPV Valves : Reliable Safety for Gas Cylinder Systems

Residual pressure valves (RPVs) are essential components that ensure optimal safety, reliability, and performance in any gas cylinder system. By maintaining a low residual pressure inside the cylinder, they prevent contamination and protect both users and equipment. Designed and tested in accordance with international ISO and EN standards, RPV valves guarantee consistent quality for applications using oxygen, nitrogen, CO2, and other specialty gases. Combining innovation and proven engineering, they offer long-lasting performance for industrial, medical, and laboratory environments.

Discover our complete range of RPV valves or contact our team for expert technical advice.