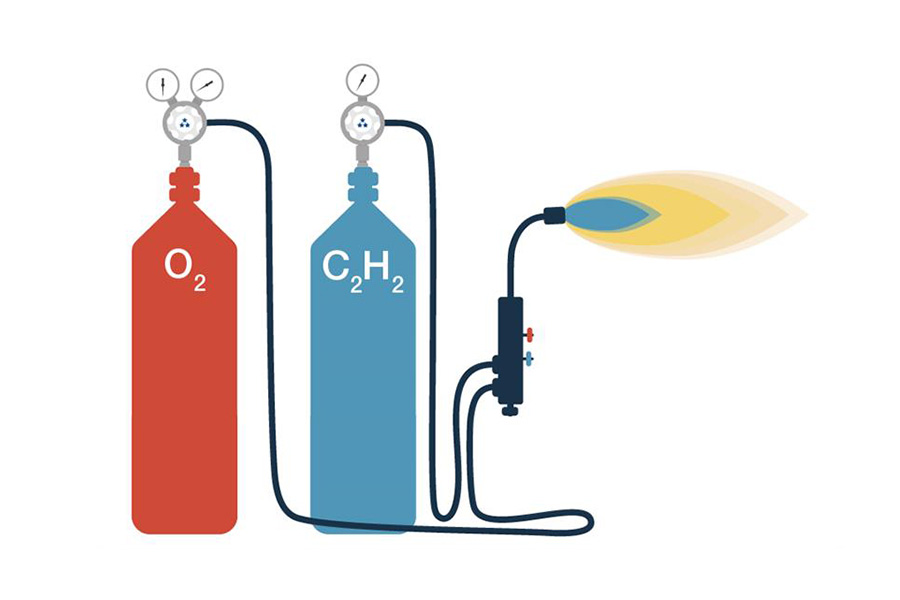

Rotarex oxyacetylene regulators are used in many industrial applications that require precise control of gas pressure and flow. They are designed to withstand harsh working conditions and support processes like welding, cutting, brazing, and heating, where stable flame control is essential for performance and safety.

Metal Fabrication and Manufacturing: They are widely used in structural steel fabrication, pipe welding, and maintenance tasks where equipment portability and process versatility are essential, and where some applications require flexible on-site solutions.

Industrial Cutting Operations: High-capacity oxygen regulators provide the flow rates required for flame cutting operations in steel processing plants, shipyards, and demolition sites, enabling quick and controlled cutting across different material thicknesses.

Brazing and Heating Applications: Rotarex regulators are an effective option for HVAC installations, metal joining, and repair operations where consistent performance over long periods of use is required.

Quality Control and Testing: In laboratories and quality control environments, Rotarex regulators provide reliable and repeatable gas flow for material testing, metallurgical analysis, and research activities requiring precise pressure and flow control.