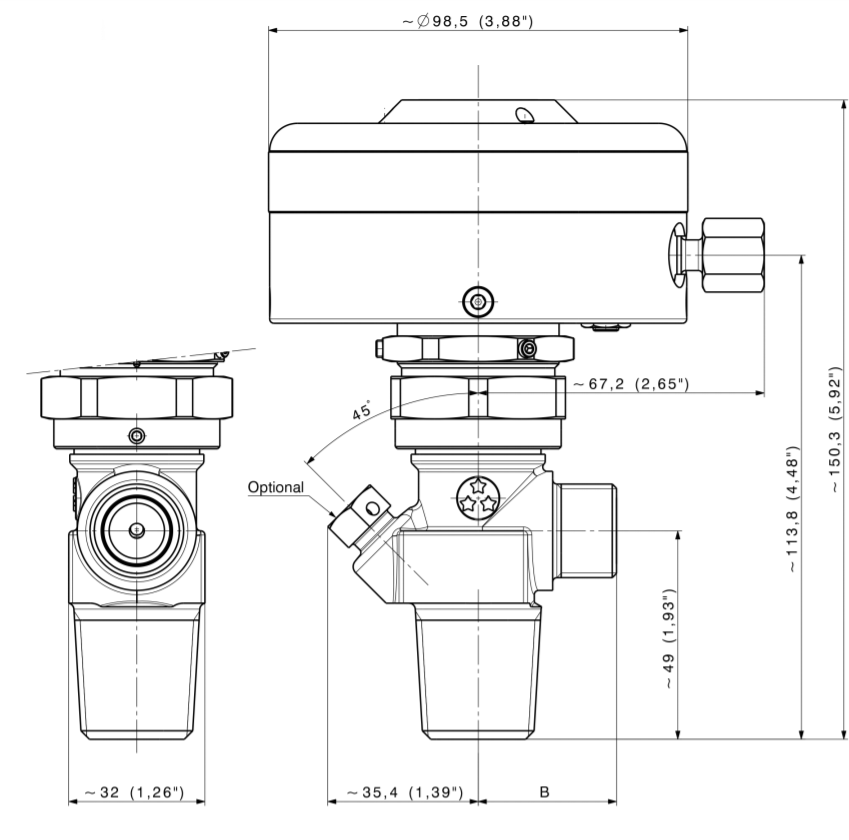

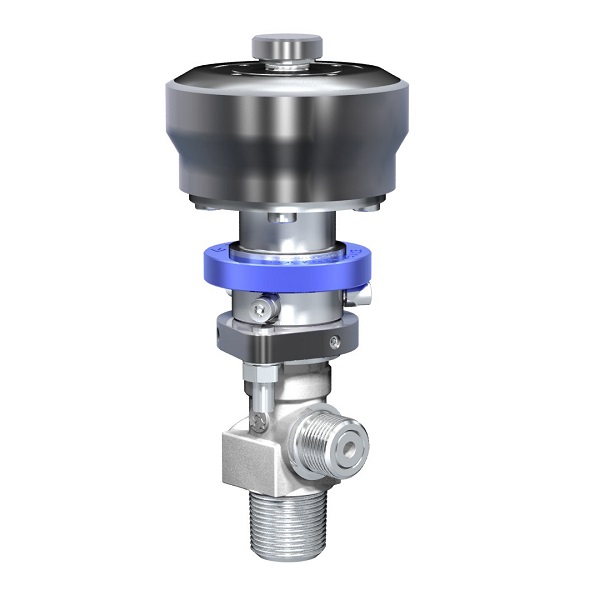

High pressure cylinder and bundle valve with pneumatic actuator for corrosive gases - D131

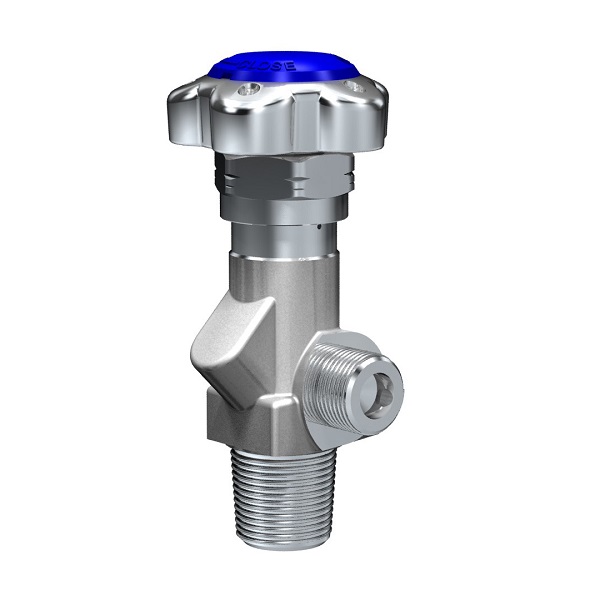

Pneumatic cylinder Valve with Packed Needle Stem Design for High Purity Gas Applications

Key advantages

- Freedom from seizure when used with corrosive gases- gas does not come into contact with the valve operating mechanism.

- Positive and effective operation-valve spindle is mechanically linked to the operating hand wheel, which only requires low closing torque.

- Long life-valve, all internal parts are replaceable

- Adjustable gland packing-in the unlikely event of a leakage occurring past the valve spindle, when opening the valve, rectification is readily achieved by retightening the gland packing nut.

- Low internal volume-this is particularly beneficial, when using the valve for hygroscopic, corrosive or high purity gases, where inert gas purging may be necessary before opening after closing the valve.

Specifications

| Connections | According (inter-)national standards and customer’s specifications |

| Working pressure | 200 bar |

| Nominal flow rate | CV = 0.25 |

| Temperature range | -20 to +65 °c |

| Body materials | Stainless steels 1.4305 (AISI 303) and 1.4435 (AISI 316L), AlSiBz and brass |

| Seat orifice size | 2.8 Mm |

| Marking | π 0029(according to TPED), manufacturing date, 3 stars, valve number |

| Leak rate | <1.10-5 m bar L/s |

Downloadable catalogs, brochures

Connect with an Expert