How Integrated Valves Are Changing Calibration Gas Management

Traditional vs. Integrated Systems

Traditionally, calibration gas setups consist of multiple separate components:

- Gas cylinders of varying sizes (from small "lecture bottles" up to large 80-liter cylinders)

- Cylinder valves

- External pressure regulators

- Connection hoses and fittings

Each approach has its own advantages and considerations. Traditional systems, while versatile and widely used, require careful management due to multiple connections and fittings, especially during cylinder changes and pressure adjustments.

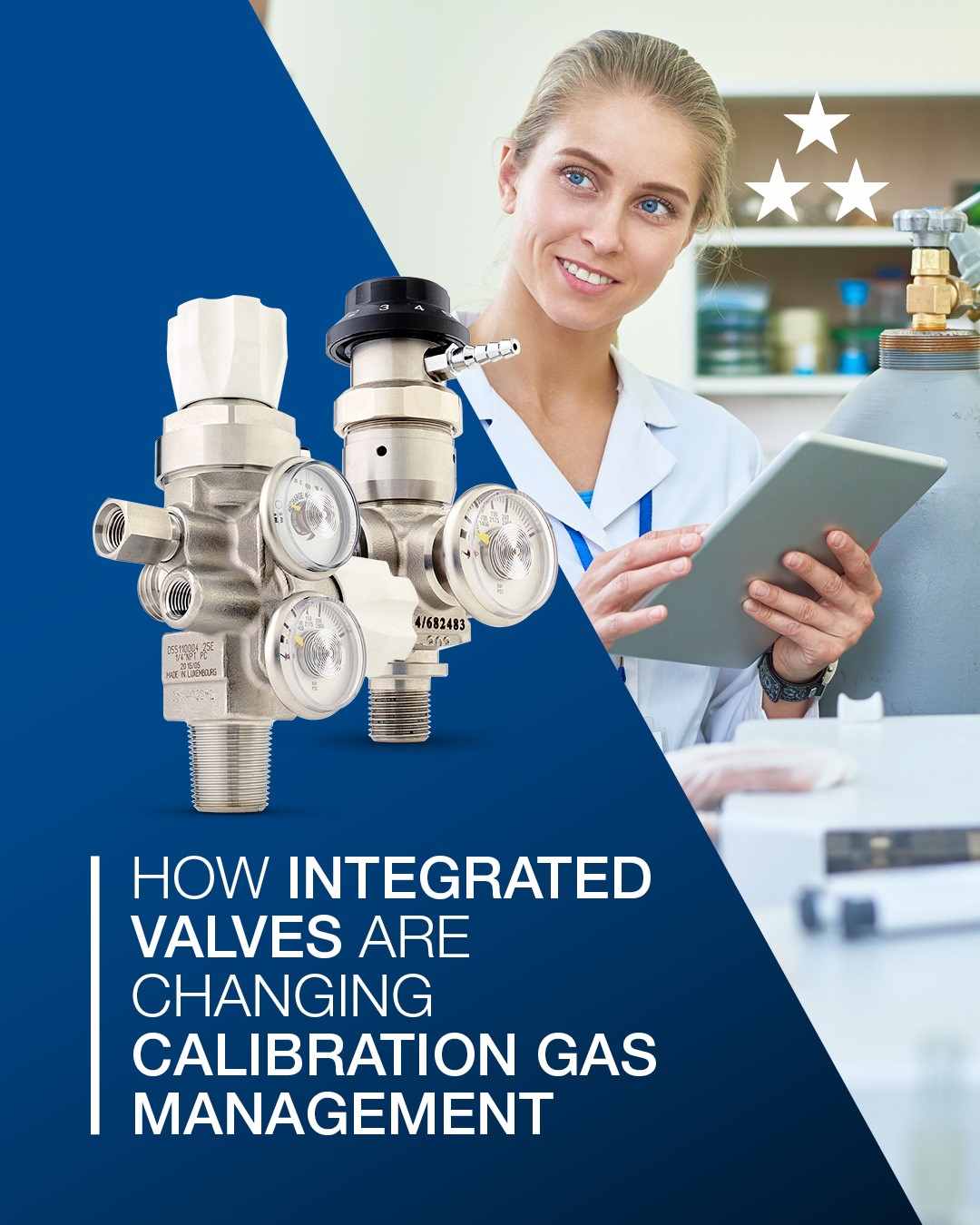

By contrast, integrated valve systems combine multiple critical elements:

- Shut-off valve

- Built-in pressure regulator

- Pressure gauges

- Safety relief device

- Flow control (Flowcal) or precise pressure control (Ducal)

This unified design reduces complexity, minimizes potential leak points, and enhances operational reliability.

Enhanced Safety

Integrated valves significantly improve safety by minimizing external connections and thus potential leak points. Rotarex’s stainless steel valves, designed for gas control of non-corrosive or toxic, high purity gases up to grade 6.0 purity (99.9999%), incorporate built-in safety features such as pressure relief devices and comply with strict ISO 22435 safety standards. This ensures secure handling even with corrosive and hazardous gases.

Improved Precision and Control

Precision is essential for effective calibration. Integrated valves like Rotarex’s Flowcal allow easy selection of precise flow rates (0.5 - 15 L/min) via a simple dial, whereas Ducal provides consistent and stable outlet pressures setting (1-4 bar) through advanced diaphragm technology. This precise control is critical for obtaining accurate and repeatable calibration results.

Simplified Operation

VIPRs streamline calibration operations. With integrated valves, technicians simply open the valve and select the required flow or pressure. Lightweight and compact (around 1 kg), these valves are particularly well-suited for portable systems and laboratory setups, significantly facilitating daily handling.

Cost Efficiency

Integrated valves reduce long-term costs by eliminating the need for separate regulator purchases, minimizing gas waste due to leaks, and reducing maintenance requirements. These factors translate into lower total cost of ownership and increased operational efficiency.

Rotarex Solutions: Flowcal and Ducal

Rotarex’s Flowcal and Ducal integrated valves represent state-of-the-art technology for calibration applications:

- Flowcal (D553): Optimized for adjustable flow control, featuring a selectable flow dial and universal hose connector.

- Ducal (D551): Provides precise pressure regulation ideal for applications requiring stable outlet pressure.

Both models feature ergonomic protective guards, ease of operation, robust stainless steel construction, and ISO-certified quality, ensuring cleanliness and meeting the requirements of diverse calibration scenarios.

Applications of Calibration Gases

Calibration gases are essential in various sectors, including:

- Environmental Monitoring: Verifying air quality sensors with precise gas mixtures.

- Industrial Hygiene: Calibration of gas detectors for worker safety against toxic or flammable gases.

- Laboratories: Ensuring accuracy of analytical instruments like gas chromatographs and spectrometers.

- Manufacturing: Calibrating instruments in production lines for consistent product quality and safety compliance.

Each application demands reliable, precise, and safe gas handling systems—requirements perfectly met by integrated valves.

Integrated valves offer a transformative improvement in calibration gas management. By simplifying operations, improving safety, enhancing precision, and reducing costs, Rotarex’s Flowcal and Ducal VIPRs represent a significant step forward. Embracing integrated valves not only streamlines calibration workflows but also boosts accuracy, reliability, and efficiency across diverse industry applications.