Get to know the Process Engineer job at Rotarex

What does a Process Engineer do at Rotarex?

The profession of process engineer consists of conceiving, improving and optimizing industrial processes. The profession is based on two main pillars : production support and project management. At Rotarex, two teams work together : the Machining Process team and the Assembly Process team.

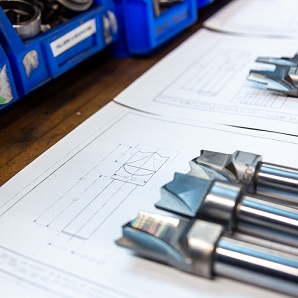

There are several functions within the Machining Process team. One part of the team is dedicated to the programming of the Selfa numerical control machines. It uses the TOPSOLID software to simulate the manufacturing processes before they are put into production. The software can be used to calculate cycle times and select tools and clamping jaws. The program is then made available to the controllers for testing and validation. It takes between 1 hour and 1 week to develop a program !

Another part of the Machining Process team is dedicated to the tools, which are made available to production in accordance with the developed programs developed. The TMS software centralizes around 20,000 production tools (stainless steel and aluminum). One person is responsible for receiving, stocking and feeding TMS. Another person,

the grinding technician, prepares the toolsor manufactures the special tools himself. The parts are either realized internally (within 2 days in most cases) or ordered externally from suppliers (within 4 to 6 weeks).

The Assembly Process team provides the documents, equipment and tools required to guarantee optimum production. It prepares precise work instructions for the assembly of the various parts, enabling the final product to be realized. In addition, it ensures the training of the operators in accordance with the quality standards and the specific

requirements of the clients. Continuous improvement is also at the heart of its mission.

On a day-to-day basis, the two process teams provide their support for production and resolve the difficulties encountered. The projects are carried out in parallel : industrialization of new products, creation of production ranges, tool management, machine purchasing, standardization of methods, monitoring of KPIs, technology watch, etc.

What's the perfect profile for a Process Engineer?

A process engineer must have a solid technical background (plan reading, knowledge of machining, mechanics/electromechanics, mechanics, pneumatics, assembly, etc.), be curious and autonomous, and be able to communicate both orally and in writing.

He must be responsive, have a great capacity for analysis, remain calm when facing of dilemmas and quickly find solutions to problems. A sense of attention, respect and good organization in the workplace are essential, as is an imaginative mindset for thinking "out of the box". Finally, a good command of English is indispensable.

A typical day for a Process Engineer?

Production sets the priorities for the day. In the absence of problems, the work concentrates on the projects and their continued improvement. Each day is different, without routine, which makes the work varied and stimulating, even if sometimes destabilizing.

What are the department's day to day interactions?

The process engineer interacts with almost the entire company, but also with external suppliers. He occupies a central role and interacts with planning, production, R&D, quality, but also with sales, the warehouse, shipping and support services. The Assembly Process team in particular has a close relationship with

the Automatec team, which is responsible for the internal manufacture of machines.

What's the superpower of our Process Engineers?

You have to show diplomacy, be a good listener and be able to work as a team to satisfy the whole world. The process engineer must be responsive and have the ability to find solutions quickly and collectively.

Composition and organization of the Process Engineering Team?

The Machining Process team consists of a dozen people, dedicated to Selfa, Lumec and transversal people. The material (stainless steel or aluminum) requires different manufacturing processes. The Assembly Process team is organized by BU. Each team is composed of two to three people, with generally one engineer, one technician

and one manager.

What do you enjoy most about your work?

It is particularly gratifying to see a product take concrete shape in production. This work, very varied, places human relations at the heart of interactions, both internal and external, thus offering enriching and essential exchanges for success. At Rotarex, the wide variety of products makes the work particularly stimulating and interesting.

Any advice for someone interested in joining your team?

You must be autonomous and capable of working in a team, communicative, patient, and have a good sense of analysis. The resolution of problems and the research of relevant information are essential. Curiosity and the desire to learn are essential, and it is important not to hesitate to ask questions, because not asking is more problematic than not knowing.