VIPR: Why the Valve with Integrated Pressure Regulator is a New Gas Equipment Must-Have

By Charles Strobel

Anyone familiar with this line of work knows just how important proper gas equipment set-up and management is to a welder's job. But it's also arduous and time consuming.

Whether its acetylene, oxygen, inert gas there are cylinders to inspect. Gas-appropriate valves, pressure regulators, gauges, manometers and other components to assemble. Hoses to thread, gas-flow to check, leak tests to conduct. Not to mention torch and attachments to inspect and purge, plus more.

Having precise, properly-functioning equipment once you start welding? Kind of a big deal. And when you're done, there are shutdown procedures to follow rigorously and components to inventory so they're always on hand.

But what if there were practical, cost-effective solutions that could simplify any part of these procedures—such as the drudgery of managing cylinder valves and the components welders attach to them? What if gasses suppliers could outfit operators with this kind of technology—dramatically reducing possible leak points and gas consumption in the process?

Meet VIPR: One Valve to House It All

Today, gas suppliers generally provide cylinders equipped with a standard handwheel valve. The customer then controls gas flow and delivery by connecting the valve to a pressure regulator with gauge, shut off valve and flowmeter.

If there was a way to eliminate the need for this extra gas control equipment, this would be of great benefit to the end-user, correct? Fortunately, there's a next-generation solution that's a win-win for operators and gas suppliers alike.

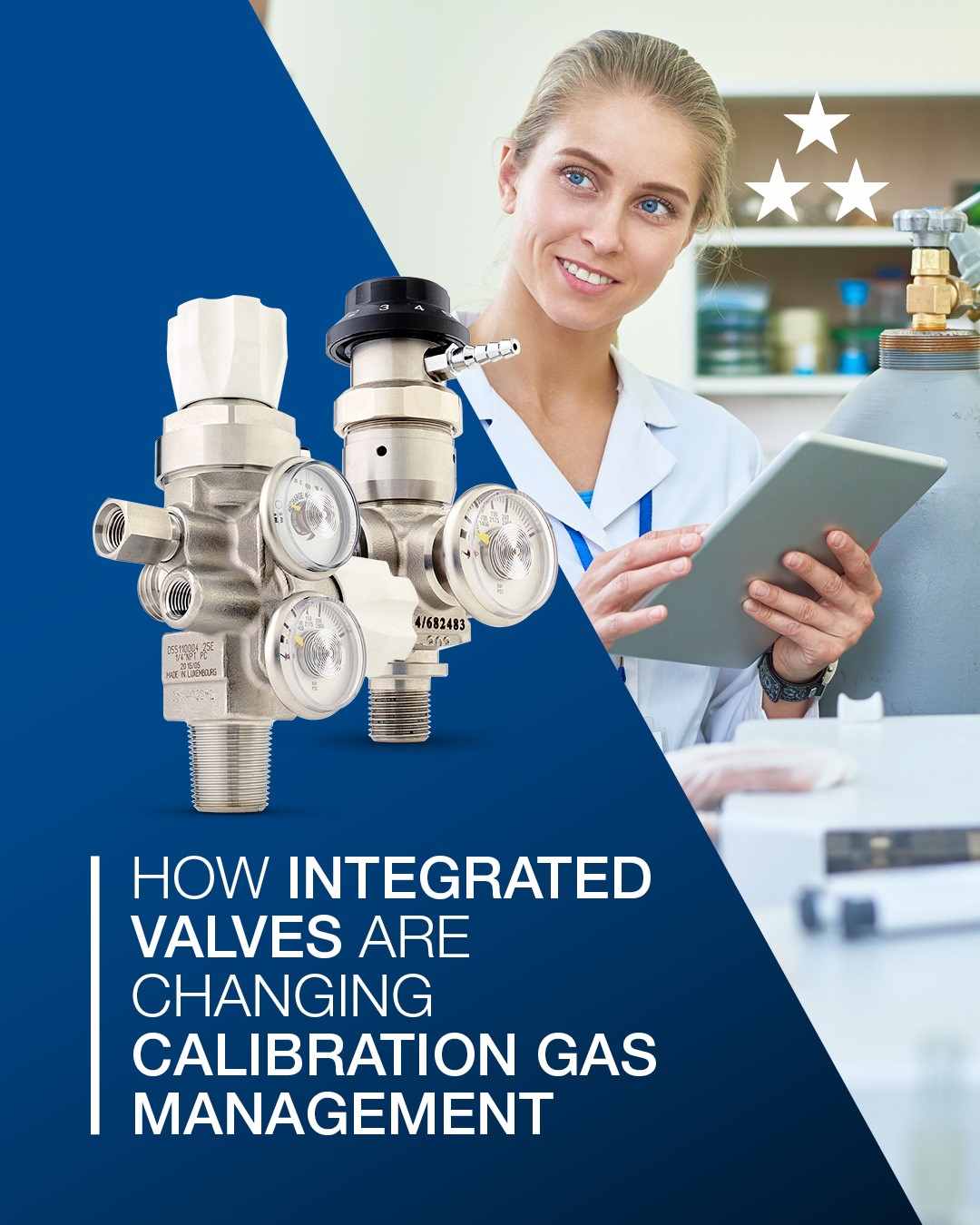

It's called Industrial VIPR (Valve with Integrated Pressure Regulator). Developed by Rotarex Indutec, Industrial VIPR is ready-to-use device with up to 11 functions in one valve—including a shut off valve, pressure regulator with gauge and flowmeter—all in a compact, mono-body design.

For operators, a solution like Industrial VIPR eliminates the burden of stocking and assembling separate components. All the gas control functions needed to safely deliver precise gas flow are integrated within one rugged shell.

The result: Faster, ready-to-go setup and shutdown processes via a safer, easier solution that reduces the total number of possible leak points and provides higher-precision flow settings.

Instead of buying several different components, they get one complete, high-quality system. What's more, overall gas consumption is reduced over time, thanks to its adjustable pressure regulator—bringing costs down further.

Proven Performance, Early Traction

Forward-edge gas suppliers are already gaining a competitive advantage by deploying cylinders equipped with VIPRs. And it's a safe bet that others will join them as industrial welders begin to see just how much value this simple, elegant technology brings to their daily operations.

In fact, in sectors where the VIPR technologies have become the industry standard, the economic advantages are irrefutable. In some countries, for instance, medical sector VIPRs account for up to 85% of the valves now in service.

What's more, gas suppliers have been able to charge customers more for the VIPR technologies, off-setting their incremental costs while building customer loyalty. And customers have been more than willing to pay a premium since the operational savings and improved safety are significant.

That said, industrial welding operators who want to continue wasting time assembling and managing cylinder valves and components can always stick to outdated handwheels.

But don't be surprised if everyone else gets smitten with VIPR and its first-of-its-kind, plug-and-work capabilities. You could even call it a must-have "must-have"—and it's available today.

To learn more about Industrial VIPR and how it can lower long-term costs and enhance the safety of your industrial welding operations, download the full CATALOGUE on this page: