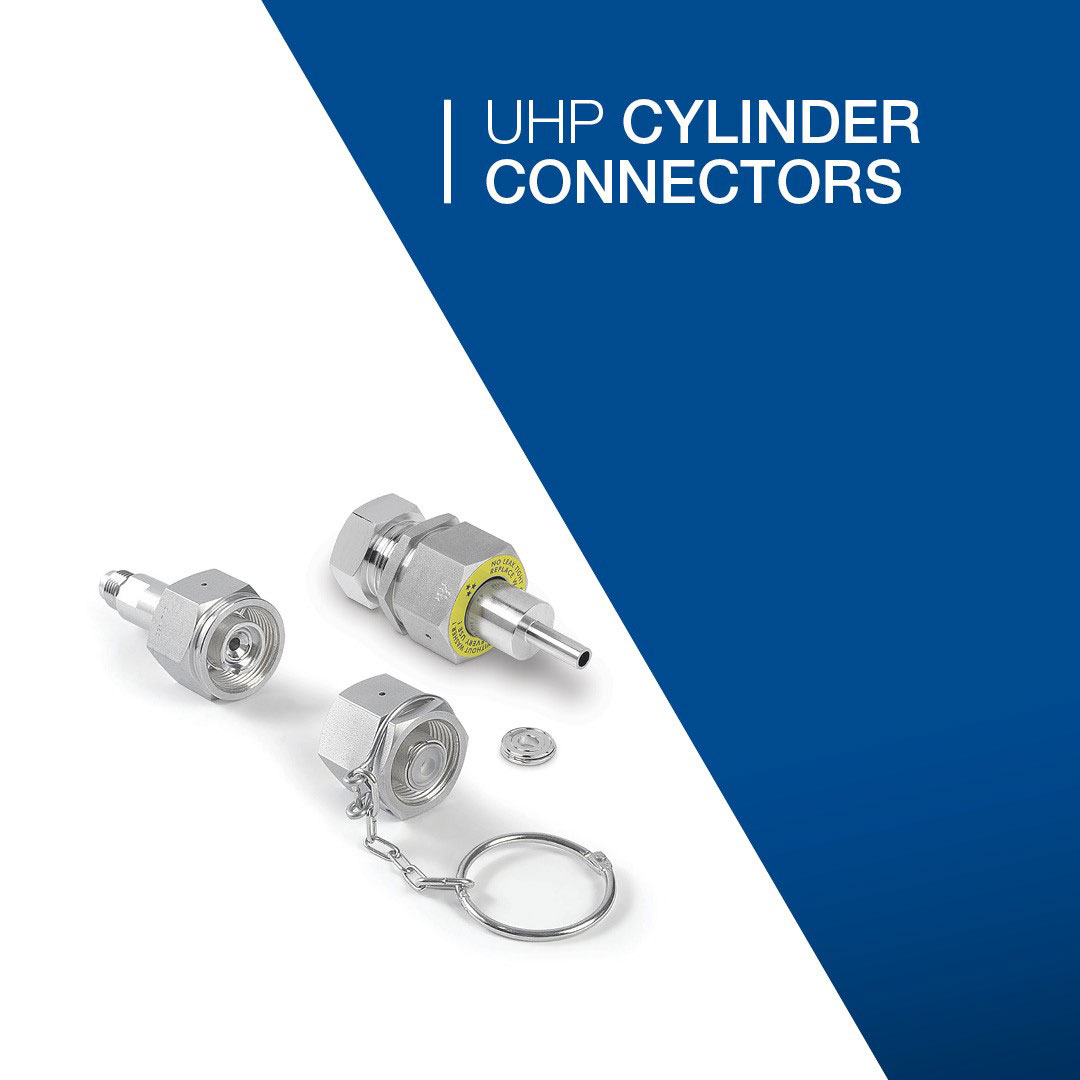

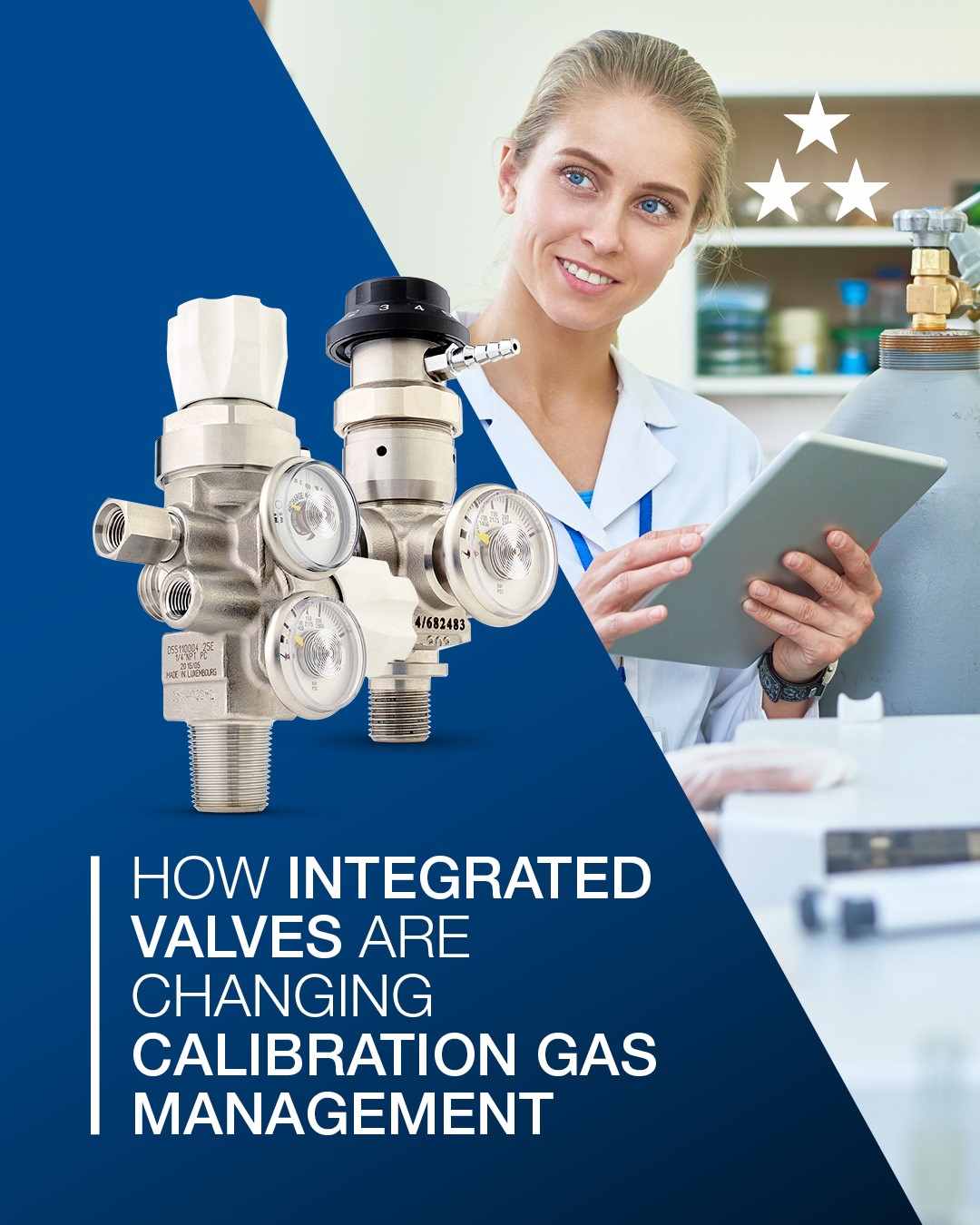

Ultra-High Purity pressure regulators

UHP pressure regulators are critical equipment in various steps of semiconductor and photovoltaic cell manufacturing processes. Processes such as diffusion, CVD, screen printing, baking, curing, oxidation, lithography, etching, and ALD demand the highest levels of purity. Rotarex has developed a comprehensive range of diaphragm pressure regulators that exceed the industry's stringent requirements.

Key features of UHP pressure regulators

- Diaphragm technology: Rotarex pressure regulators ensure stable, precise pressure and flow

- A very high level of purity: UHP gases are used in applications where gas purity is essential

- Reliability and safety: excellent leak tightness is a must when toxic and corrosive gases are involved