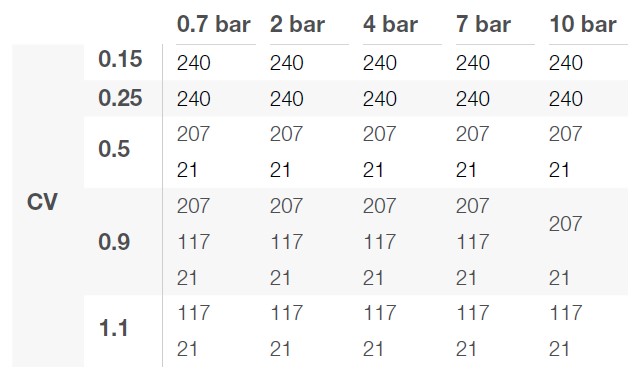

Column 2 | Regulator type | Outlet Pressure | Seat material | Cv value | Body material | Surface finish | Porting configuration | Connection | Actuator | Options | Inlet pressure |

RX | 40 | 01 | K | 015 | S | S | 2W1 | 4F | M | H | 021 |

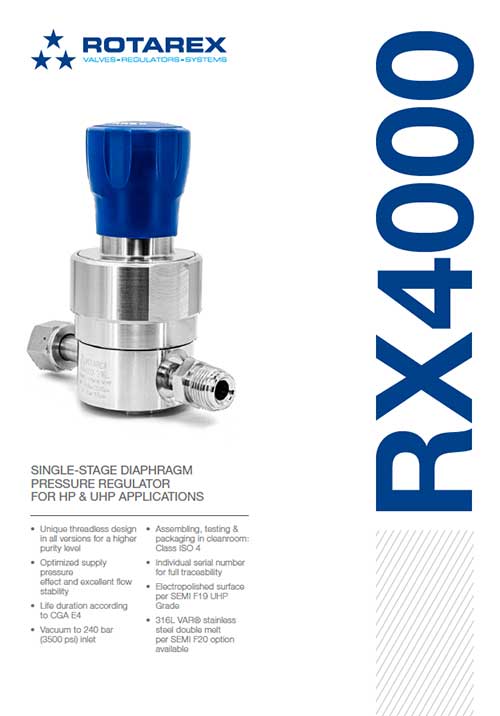

** Includes Hastelloy C22 Poppet, wetted spring & diaphragm

*** Standard gauge ports are Metal Face Seal ¼” Male

*** Standard gauge ports are Metal Face Seal ¼” Male