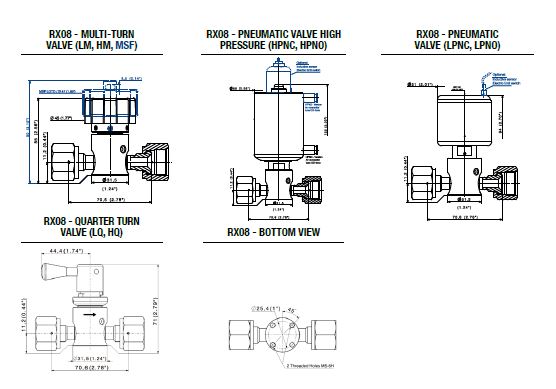

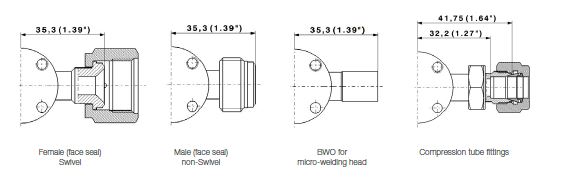

Surface finish | Maximum delivery pressure | Porting configuration | Body material | Seat material | End connection | Options | |

RX08 | S | LM | 2W1 | - | K | V 3/8 F | FT |

* Add NO for normally open or NC for normally closed

** On demand

*** On HP and LP actuators only

** On demand

*** On HP and LP actuators only