Safety equipment for acetylene plants

Rotarex offers a range of acetylene safety devices used to stop the progression of a flame in an acetylene filling plant. Whether the arrestor is placed just after the gas cylinder where the pressure is higher or further in the gas network distribution pipelines where the pressure is lower, Rotarex’s range covers all applications.

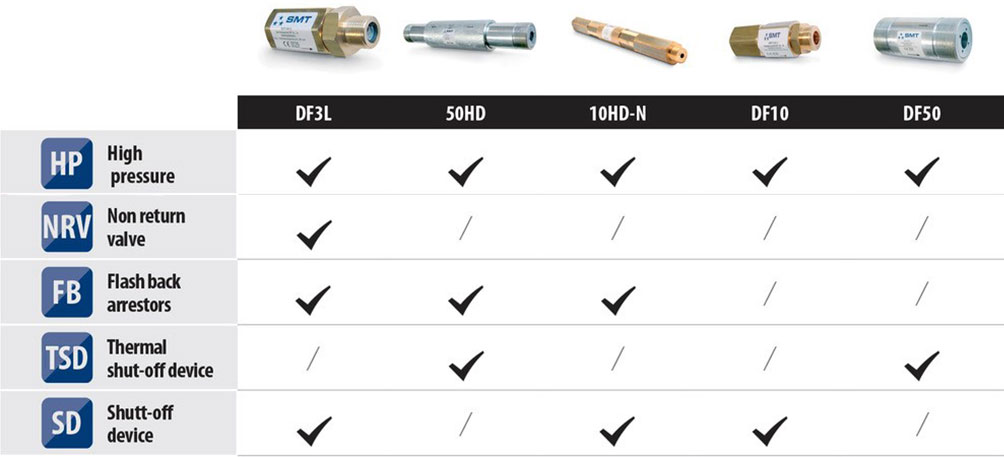

The range includes seven different kind of safety devices: five are meant for high pressure (HP) and two for low pressure (LP) applications. HP devices can handle pressure up to 25 bar while LP devices up to 1,5 bar. The HP safety equipment is compliant with EN ISO 15615, the LP ones with EN ISO 5175-1 and EN ISO 5175-2. Each product is as well in conformity with PED 2014/68/EU.

Choosing the appropriate device depends on the application required functionalities as defined by the applicable standard(s). Pressure/flow drop needs to be considered when designing a network to make sure it matches the application requirements.

The products differ from each other in the features they contain:

- The non return valve feature prevents gas from passing in the opposite direction to the normal flow direction;

- The flashback/flame arrestor arrests a flame front. It prevents a flame progression in both possible directions. A sintered metal element lead to flame quenching;

- The thermal shut-off prevents excessive temperatures, it closes automatically at a certain temperature and cuts off the gas flow;

- The shut-off device is a pressure-sensitive cut-off valve. It stops the gas flow when the downstream pressure varies above a certain level under the effect of a deflagration or acetylene decomposition.

Want to know more? Contact us!