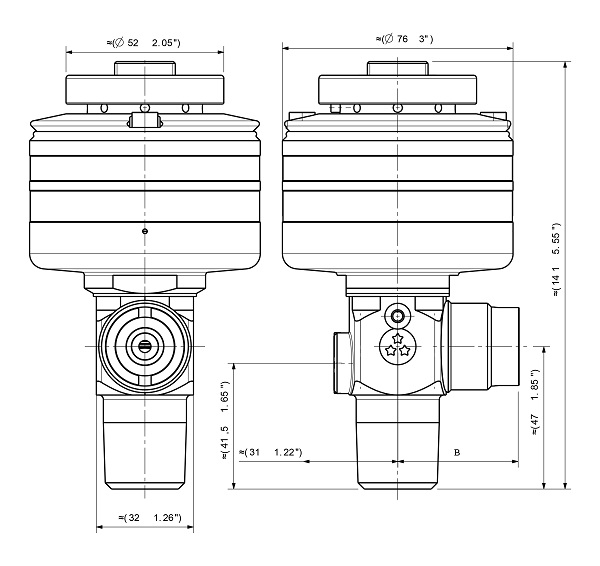

Tied diaphragm cylinder valve for fluorine mixtures with pneumatic actuator - D386S

The D386S ensures the highest levels of purity and safety for applications using fluorine gas mixtures, such as cleaning non-plasma deposition chambers and diffusion furnaces for silicon-based films. Designed with the challenges of fluorine-nitrogen mixtures in mind, this UHP cylinder valve incorporates specialized features to enhance operational safety and maintain the purity of F₂/N₂ mixtures, supporting contamination-free manufacturing

Key advantages

- Pneumatic actuation

- Valve is designed normally closed

- The tapped vent hole allows the connection to a leak detector

- Gas will not come in contact with the valve operating system

- Backed up welded diaphragms provide a high leak tightness integrity up to 10-8 mbar.l/sec

- Reduced dead spaces and gas wetted volumes allow easy purging process

- No particle generating threads in the gas wetted part

- Metal to Metal seat, fully suited for fluorine applications

Specifications

| Connections | According (inter-)national standards and customer specifications |

| Working pressure | 200 bar |

| Body materials | Stainless steel 1.4435 (AISI 316L), Hastelloy® C22, Nickel 200, Monel® 2.4375 (Monel 500 K) |

| Temperature range | -40 to +65 °c |

| Leak rate | 1.10-8 M bar l/s |

| Seat Orifice Size | 4 Mm |

| Marking | π0029 (according to TPED), 3 stars, valve number, manufacturing date |

| Nominal flow rate | CV=0.25 |

| Gas type | N2/F2 |

Downloadable catalogs, brochures

Connect with an Expert