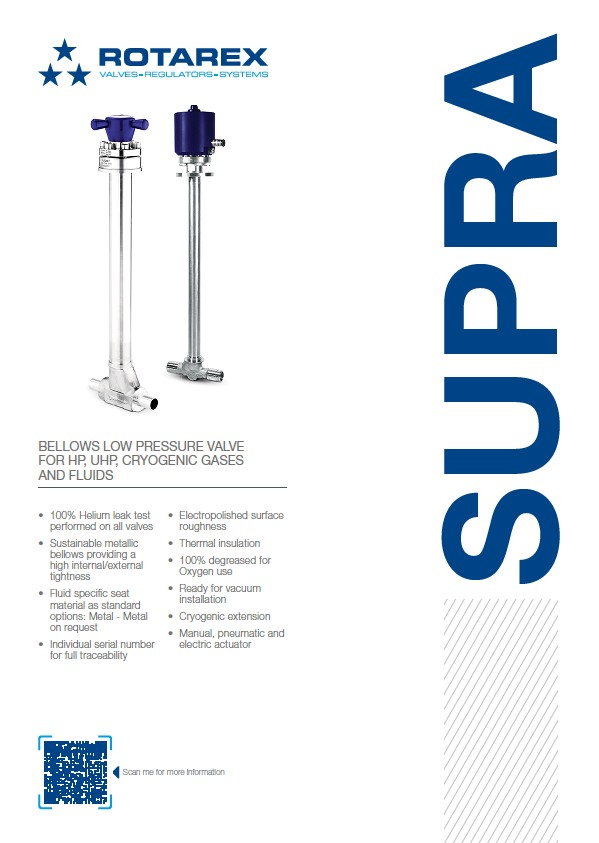

Size | Actuation | Body material | Seat material | End-connection (1) | Surface finish | Options (2) | |

SUPRA | 08 | MI | I | /K | BWO | - | - |

(1) Size to be defined by customer and ROTAREX

(2) Combinable

(2) Combinable

_it3mul_EEGvS5.jpg)