Pneumatic Diaphragm Valves – Efficient Flow Control for Electronic Applications

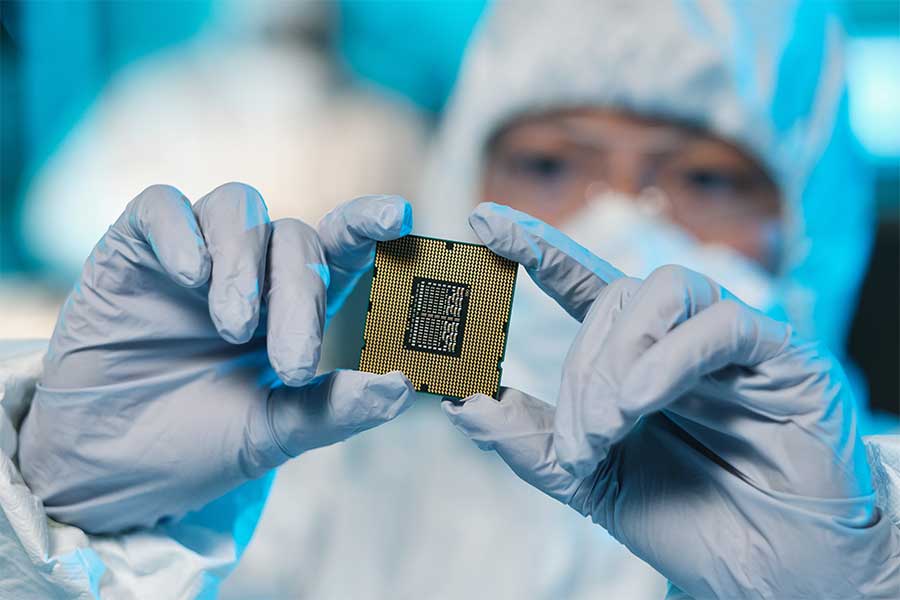

Combining precision and reliability, Rotarex pneumatic diaphragm valves are suitable for use in semiconductor and photovoltaic cells manufacturing and other processes requiring ultra-high-purity and optimal performance, where purity, leak tightness, and durability are critical.

To meet a wide range of system requirements, our UHP line valves are offered in a wide variety of configurations, with inlet pressures from 10 to 240 bar, flow rate from 0.2 to 3.5, and seat diameters ranging from 4 to 20 mm, providing optimal performance across ultra-high-purity applications. Some models are also available with a forged body (F series).

Discover our full series and find the solution that best meets your needs or get in touch with our specialists, who will be happy to guide you toward the right solution.

_U93uw1.jpg)